Laser Cutting

Call us for a quote!

Why Would You Need A Metal Degreasing Line?

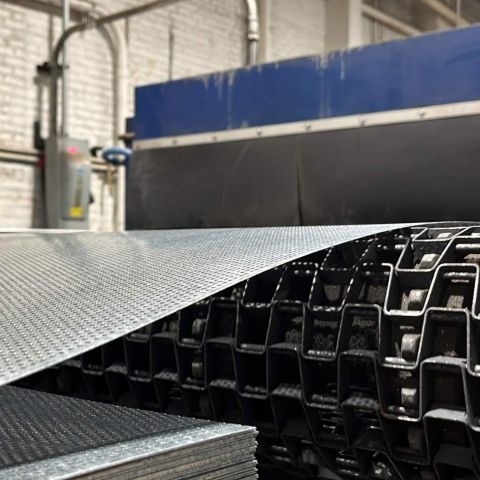

Due to the manufacturing process, perforated metal components often acquire grease or other oils. To protect the equipment, lubricants are applied before punching as the metal passes through the press.

Therefore, custom metal degreasing services are necessary because any remaining residue could cause complications. Grease can interfere with the application of coatings and lead to imperfections in precision parts.

Fortunately, our metal washing line ensures that parts are clean and in their best condition. And we can "toll process" your parts on it. Just ship your material into our facility, give us the date you need, and we'll take it from there! Our specifications are below.

What Can You Run through A Degreaser?

- Perforated Sheets

- Solid Sheets

- Perforated Metal Coils

- Solid Metal Coils

- Formed Perforated Sheet Metal Parts

- Formed Solid Sheet Metal Parts

- Outside Parts and Components, including stamped, cast, machined, and welded material

- Parts with Protective Coatings (e.g. blue)

- Plastic Material

Max Specifications

- Maximum Width: 60"

- Maximum Height: 12"

- Maximum Length (Sheet): 20'

- Maximum Width (Coil): 60" Wide

SPECIFICATIONS

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

HOW TO USE

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

DETAILS

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

BESTSELLERS